Environmental Health and SafetyPromoting a safe and healthful environment for living, learning and working |

HOW TO GET A RESPIRATOR: PROCESS FLOW

Step 1: Workplace Evaluation for Exposure/Hazard Assessment

The first step is to conduct a workplace hazard evaluation to determine:

- whether atmospheric contamination exceeds or is likely to exceed the hazard limit and

- the most effective and efficient means of respiratory protection for you

The RPPA will work with you or your supervisor to find methods to reduce the levels of atmospheric contamination. If such methods offer insufficient protection and respirators are required, proceed to the next step, medical evaluation.

Step 2: Medical Evaluation

Because the use of respirators can place a burden on the body and aggravate some medical conditions, medical evaluations are required before a worker is fit-tested and told to wear a respirator. Of special concern is the health of workers who suffer from heart disease or respiratory problems.

Print and complete the following forms:

- Medical Evaluation Contact Info Form

- UHS OSHA Respirator Form

Drop off /send the completed forms to:

Occupational Health Nurse

University Health Services

150 Infirmary Way

University of Massachusetts, Amherst 01003-9288

The Occupational Health Nurse (OHN) will contact you for discussion and or appointment.

After determining the employee’s ability to use a respirator, the OHN will provide the RPPA with a written recommendation stating whether the employee is medically able to use a respirator or not and if there are any limitations on respirator use.

NOTE: Employees are not permitted to wear respirators until the OHN or a physician or other licensed healthcare professional (PLHCP) has determined that they are medically able to do so. Any employee refusing the medical evaluation will not be permitted to work in an area requiring respirator use.

Step 3: Respirator Selection

After receiving medical clearance for respirator use, make an appointment with the RPPA at EH&S. At this meeting the RPPA will advise you on the types of respirators to purchase. It is the PI/supervisor's responsibility to provide, and pay for, all personal protective clothing and equipment, including respirators.

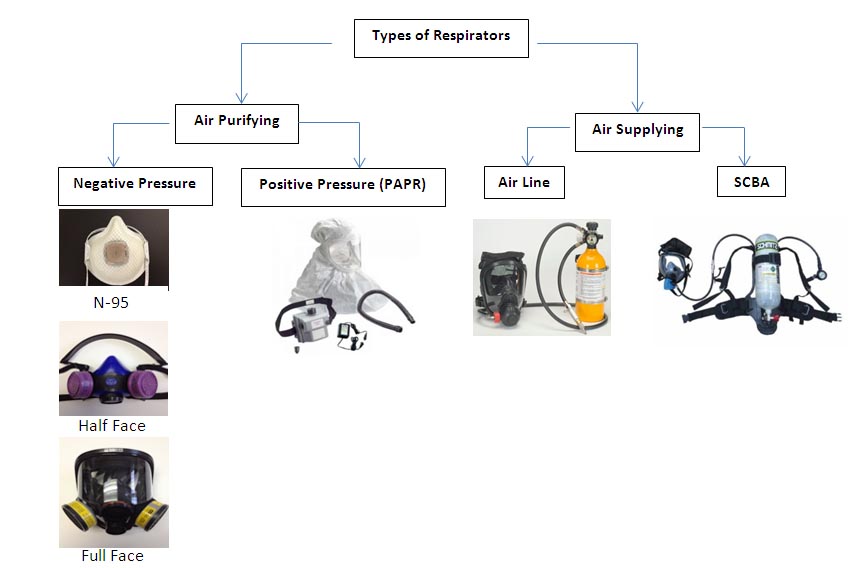

The flowchart below gives a general overview of the types of respirators and their function:

(PS: this is not the comprehensive list of available types/models of respirators)

Step 4: Fit Testing

Call the RPPA to make an appointment for fit testing. Once the respirator type has been finalized, the RPPA will conduct a quantitative fit test (QNFT) using PortaCount machine specific to the make, model, style, and size of the respirator intended to be used. The RPPA will conduct initial and annual respirator fit testing for all respirator users in accordance with Appendix A of the OSHA Respiratory Protection Standard, 29 CFR 1910.134.

Repeat fit testing may be required if the respirator wearer or PI/supervisor notices changes in the wearers' physical condition that could affect fit, and if a different face piece is used.

Annual fit testing and training is required. The RPPA will notify you when it's time for renewal.

There is no charge for fit testing by EH&S.

Step 5: Training

Training on proper respirator usage, maintenance, storage and repairs will be provided at the time of fit testing. Respirator training routinely covers:

- Why the respirator is necessary

- What protection the respirator can give if properly fit and maintained

- The limitations of the respirator

- How to inspect, put on, remove and use the respirator

- How to do user seal checks; Positive pressure and negative pressure checks

- How to use the respirator in emergencies, including conditions in which the respirator malfunctions

- How to recognize medical signs and symptoms that may prevent or limit effective use of the respirator

- The general requirements of OSHA’s respirator protection standard.

Retraining must be given at least annually, or when changes in the workplace or in the type of respirator used makes previous training obsolete. New or transferred employees must be given their respirator training before being required to use the respirator.

WHAT ARE THE REGULATIONS AND POLICIES GOVERNING RESPIRATORY PROTECTION?

- Respiratory Protection. - 1910.134 - OSHA

- Appendix A to Respiratory Protection 1910.134: Fit Testing Procedures

- Appendix B-1 to 1910.134: User Seal Check Procedures (Mandatory)

- Appendix B-2 to 1910.134: Respirator Cleaning Procedures (Mandatory)

- UMass Amherst Respiratory Protection Program Manual

© 2013 University of Massachusetts Amherst • Site Policies Environmental Health and Safety - 117 Draper Hall, |